• Monitoring & breakdown prediction

• Lubricant & repairs schedules

• Reduce maintenance spend

CMS provide an optimised maintenance programme that reduces machinery downtime risk factors. We create a database to proactively manage and monitor the operating performance of your machinery.

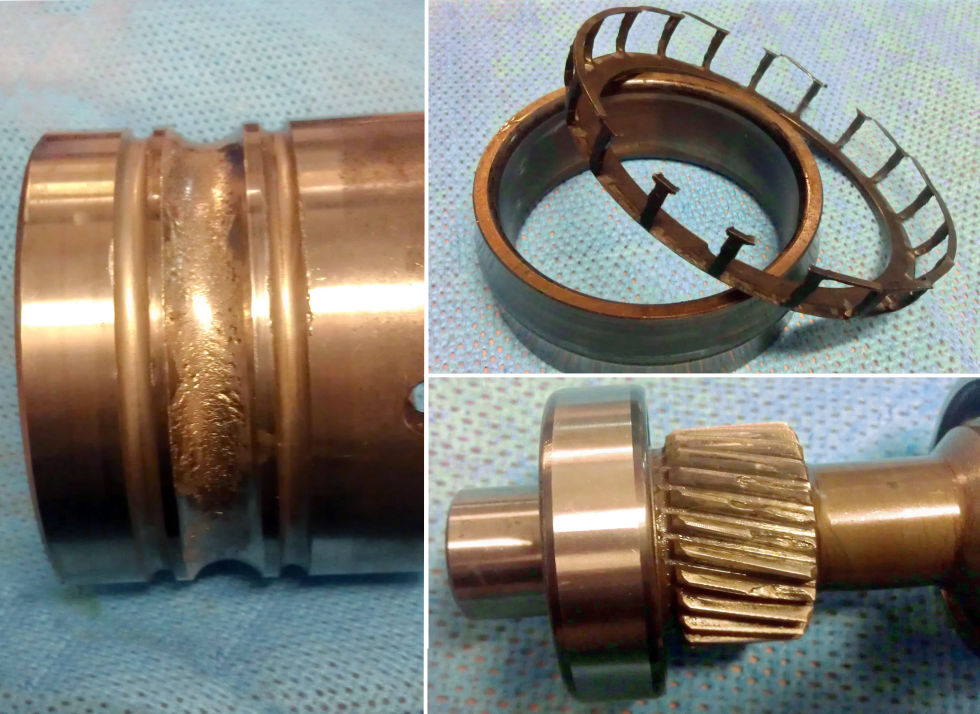

Condition monitoring is the process of monitoring vibration, temperature and other key parameters in machinery to identify changes that could indicate a developing problem. It is a major part of predictive maintenance as implementing condition monitoring allows for maintenance to be scheduled and preventive actions taken to prevent further failure and subsequent unplanned downtime.

Traditional condition monitoring was mainly based around vibration analysis, but more modern, innovative techniques use sensors to measure different parameters in real time and can send an alert when a change is detected.

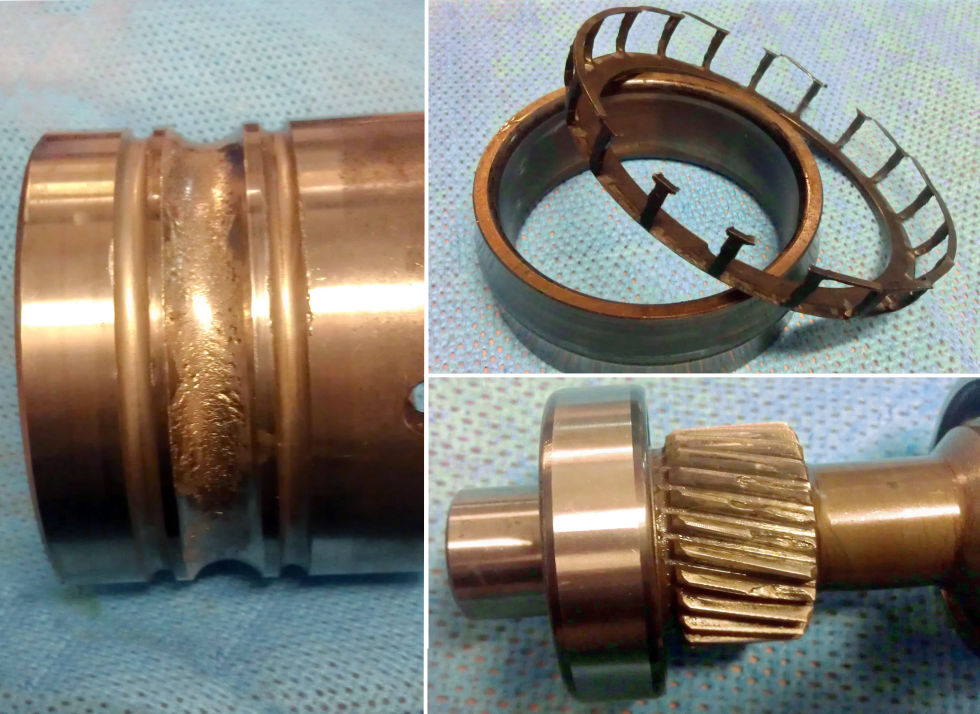

Lubrication Management is important for identifying required improvements to reliability of machinery. CMS aims to reduce maintenance spending by optimising lubrication.

CMS lubrication management ensures best practices of lubrication and Fluids Management by working with our customers to manage oils and greases from procurement, storage, treatment and application, through to their disposal.

The advantages of lubrication are:-